Printed electronics

Printed electronics is a set of printing methods, such as screen and inkjet printing, used to create electrical devices on various substrates. Printed electronics technology allows printing electrical circuits quickly and economically making them appealing to a broad range of industries. Tekniseri has customers using this technology for several applications, main products being membrane switches. Also, sensors and heating elements have been implemented using printed electronics technology. New applications are innovated all the time as the substrates and printed materials become thinner, lighter and flexible enough to be integrated into various production lines.

Membrane switches and keypads

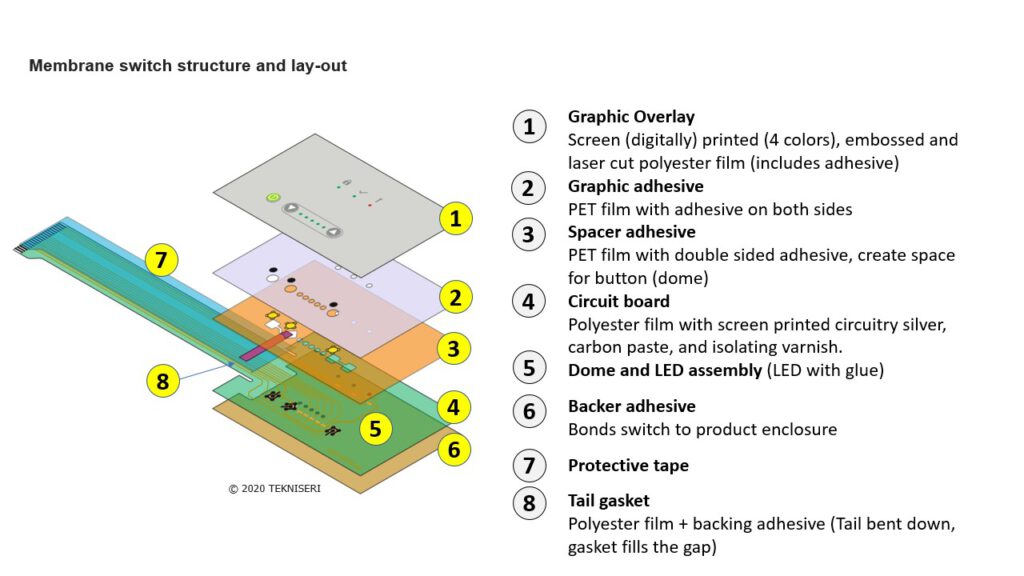

Membrane switches are control panels manufactured of thin plastic film using printing technology. They are used in low voltage and current applications where the switch is reversible. Membrane switches is generally installed in control circuits. A membrane switch is reliable and easy to design to make it both visually and functionally suitable for the final product.

The switch can be manufactured to be directly integrated into the plastic film, or the connection can be via separate pushbutton. When using a separate pushbutton, user gets the feeling as he was using a mechanical pushbutton. Windows and screens and special effects such as embossing can also be added on a membrane switch’s surface.

Membrane switches are splash- and dustproof and therefore are protected against other external factors that could damage the device.

Printed sensors, antennas and circuits

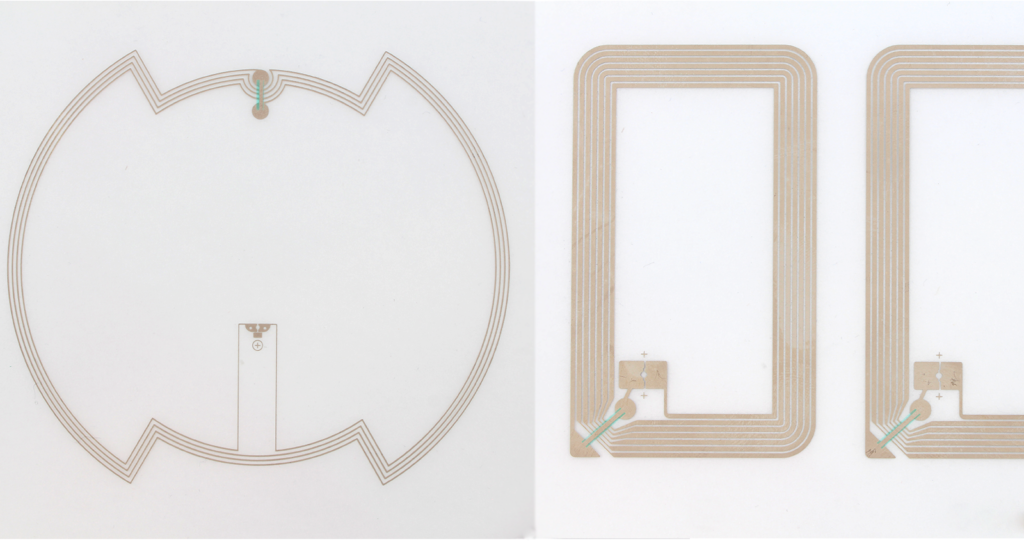

The Radio Frequency Identification (RFID) technology enables identification of objects from a distance and without line of sight. The RFID tag communicates with the reader via radio signals through antennas through electromagnetic or inductive coupling. Tags consist of an antenna and an Integrated Circuit (IC) chip mounted on a substrate.

Printed heating elements

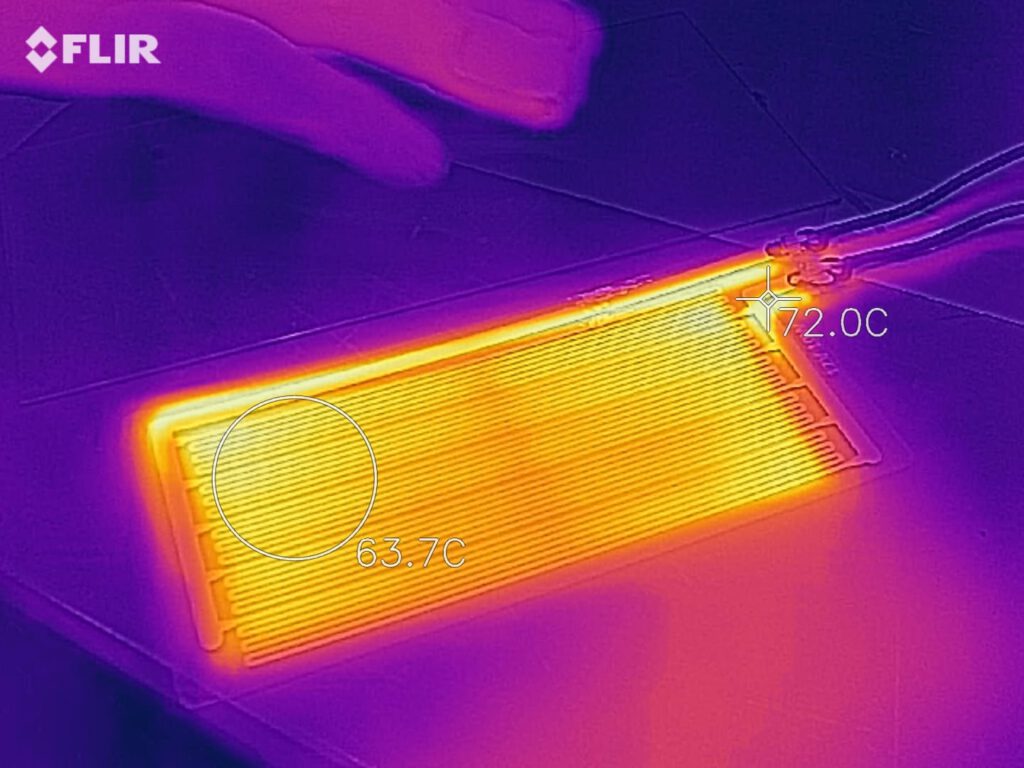

Screen printing can be used to produce flexible heating elements that are integrated as a part of seat heating or clothing. Heating elements are produced by printing with conductive screen printing ink on suitable plastic substrate.

Manufacturing process and design allow the product to be flexible with limited dimensions. The technology guarantees low energy consumption and thermal uniformity for the product. The heating elements are thin, light and easy to cut into specific shapes. Installation is done by laminating printed heating element onto surface using appropriate adhesive.

Printed heating element features include good heat transfer, low energy consumption, thinness and cost effective manufacturing structure.